Increase Facility Communications, Safety, and Operability With Compliant Pipe Labeling

ANSI ASME Standards for Pipe Labeling

Pipe labels efficiently & effectively communicates important information to facility personnel to keep them safe and your operation running efficiently. The American National Standards Institute (ANSI) offers a recognized and respected approach for labeling piping systems. While the ANSI/ASME Standard for pipe labeling provides facilities with increased safety, communications, and operability, it is important to understand how to create and maintain an ANSI/ASME Compliant Facility.

The standards for pipe labeling regulate the letter size, marker length, marker color, and location of markers to be installed. ANSI/ASME Standards for pipe labeling provide a specified primary & secondary means of pipe marking. To follow ANSI/ASME Standards for pipe labeling you need to apply the standards to both purchasing & installation of pipe marking.

Applying ANSI/ASME Standards When Purchasing Pipe Labels:

- Primary Pipe Label: The directional arrow and pipe marker legend are the primary means of identifying pipe contents. Pipe markers are to indicate both contents of the pipe and its direction of flow. Arrows at both or one end of the marker indicates flow direction.

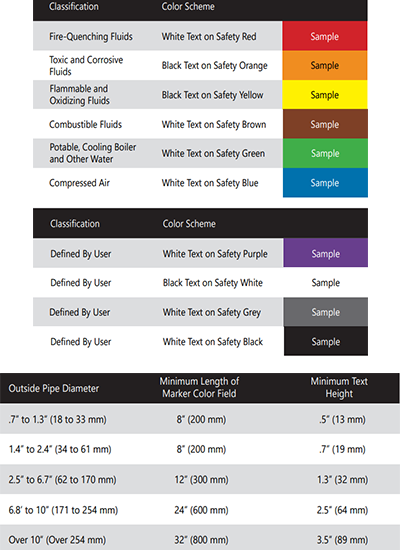

- Secondary Pipe Label: The color code of your pipe marker is the secondary means of pipe labeling. The current version of ANSI/ASME 13.1-2020 code uses a color scheme with six standard color combinations and four defined by user combinations. Pipe marker colors are based on the charismatic characteristics of the hazard of the contents of the pipe.

- Pipe Marker Size: Pipe diameter determines the appropriate marker and text size.

Applying ANSI/ASME Standards When Installing Pipe Labels:

Pipe Marker Placement: In order to comply with ANSI/ASME Pipe Marker Placement, you need to consider the intended installation spot of your pipe marker. Before installing your pipe markers, you need to make sure your markers can be easily seen from a normal angle of approach. Pipe markers are required at the following locations:

- Adjacent to all valves and flanges

- Adjacent to all changes in direction

- On both sides of wall or floor penetrations

- At intervals on straight pipe runs sufficient for identification

While creating and maintaining an ANSI/ASME compliant environment can increase communications, safety, and operability throughout facilities - we understand it can be a challenging process to start. We can help guide you through the process of purchasing & installing compliant pipe labeling. To learn more, or to start the process: